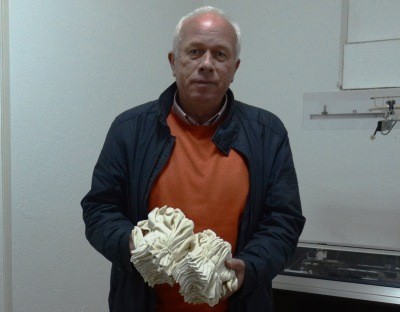

May 2016—Ukras Ltd. is a small Serbian company established during the economic downturn of the 1990s. For more than 20 years, owner Svetozar Milovanović struggled to develop a steady business for the production of protective gloves.

Historically, it has not been easy to do business in Serbia, especially in underdeveloped municipalities, according to Milovanović. “With the economy struggling with liquidity and delayed payment collection, it was very difficult to find reliable buyers,” he says.

His first breakthrough happened in 2004 after he received a state-of-the-art machine from USAID to vulcanize gloves. But production really surged in 2014 when, with USAID’s assistance, Ukras obtained “CE marking,” which certifies that a product complies with the essential requirements of the relevant European health, safety and environmental protection legislation.

The CE marking increased buyer response from larger, trustworthy clients required to purchase products that carry the CE mark. Milanović first secured orders for steady supplies from Tigar, a Serbian tire manufacturing company, and later a large contract with Fiat Automobiles Serbia (previously known as Zastava Automobiles).

In 2015, with an eye toward opening new markets for Serbian products, USAID arranged for companies from underdeveloped municipalities to participate in the Slovenian Forma Tool Trade Fair. As a result of connections made there, Ukras procured a monthly sales contract for 15,000 pairs of customized protective gloves from Gorenje, a Slovenian company operating in Serbia, to the tune of around $5,100 (550,000 Serbian dinars) per month in revenues.

“Our production increased by 40 to 50 percent. We are barely able to meet demands and are producing in 24-hour shifts,” said Milanović.

Inspired by the process of obtaining CE mark certification, Ukras has started to think more intently beyond the local market. With USAID assistance, the company is now in the process of obtaining certifications for other key production standards, including ISO 9001 (quality management system) and ISO 14000 (environmental systems). They are enthusiastic that these certifications will expand possibilities for export to foreign markets.

Recently, Milanović turned over the business to his daughter Tijana, who has brought new spirit and ideas to the company. Ukras is now a fully female-run business with production facilities in one of the poorest municipalities in South Serbia, Vladičin Han, where businesses are typically owned and managed by men. The future looks bright for Ukras.

Assistance to Ukras is part of USAID’s Private Sector Development Project, a four-year, $6-million activity launched in July 2013 to strengthen private sector firms in 12 municipalities in the economically disadvantaged regions of south and southwest Serbia.

LINKS

Follow @USAIDSerbia, on Facebook, on Flickr, on YouTube

Comment

Make a general inquiry or suggest an improvement.